SIM CON DRILL

INNOVATIVE FILTER MODULES FOR

THE SEPARATION OF

MICROPLASTIC FROM WASTE WATER

MICROPLASTIC REDUCTION

PROJECT DESCRIPTION

Microplastics are discharged into our wastewater and the environment every day. Thus far wastewater treatment plants are not able to sufficiently reduce microplastics. Therefore our focus is on the development of a filter that is ready for serial production, which enables the filtration of particles down to 0.01mm (this equals the thickness of household aluminium foil) based on the patented cyclone filter. Due to its special technology, this filter is clogging and maintenance-free and not a disposable filter. Once the prototype has been built, it will be tested in a treatment plant using real wastewater.

PROJECT REALIZATION LEVEL

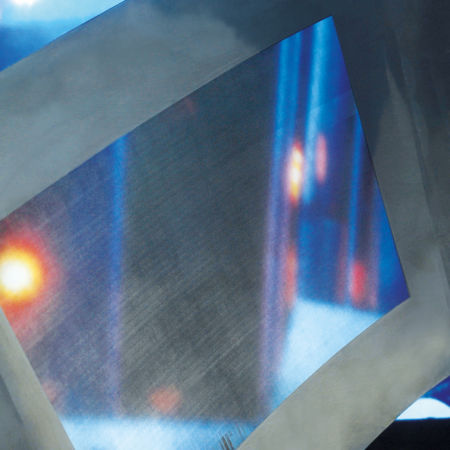

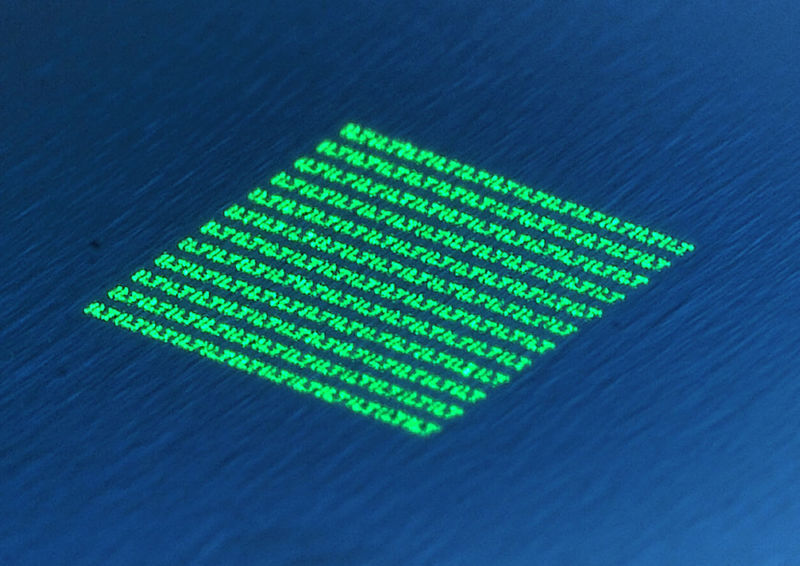

The project began with the development of a laser drilling process to produce 10µm holes in thick metal sheets. Today, the production of these small holes in 200µm thick sheets is possible. In the following step the process will be scaled up for serial production. First test runs entail the integration of drilled test foils into the cyclone filter to start testing on functional and flow properties. Concomitantly, a process simulation was developed to calculate optimized parameters. In order to ensure optimum total flow-through, an in-line process control for the laser process is currently being developed to check whether each hole has been entirely perforated.

TEAM

back row:

Peter Abels (Fraunhofer ILT)

Burkhard Hoche (Lunovu GmbH)

Georg Klass jr. (Klass-Filter GmbH)

Thilo Bartels (Fraunhofer ILT)

front row:

Dr. Markus Niessen (Fraunhofer ILT)

Dr. The-Quan Pham (OptiY GmbH)

Andrea Lanfermann (Fraunhofer ILT)

Dr. Claudia Riester (LaserJob GmbH)